Medium pressure servo systems

hydraulics reduce noise levels

Cost efficient, easier installation and

maintenance, higher reliability and extended

lifetime. Quieter than a high-pressure system.

Precise Manoeuvring

A variable displacement pump delivers the

exact amount of oil needed for the propeller

pitch movements. The valve mechanism

automatically adjusts the oil flow to enable

smooth and highly precise manoeuvring via

a direct hub linkage mechanism.

One oil type for lube and

servo system

• Gear

• Pitch mechanism

• Multiple propeller shaft sealing system

No forced cooling

for lubrication oil

The HPU uses natural cooling,

as the oil reservoir is located in

the thruster gearbox.

Protection of the

marine environment

– is a growing concern

throughout the shipping

industry. Oil leakage from

thrusters can harm even

the best of reputations.

Brunvoll designs systems

focused on preventing

such pollution.

Easy checking of

oil condition

Valves accessible from the top

of the thruster are connected both

to the seal safety chamber and

gearbox bottom. This makes it easy

to drain oil and detect any traces of water

or particles in the oil – an early warning.

Overhaul without

removal of gearbox

While the gearbox is still in

the tunnel, one can:

• Change individual propeller

blades or blade seals.

• Remove the propeller hub to

change shaft seals.

• Take out the whole propeller

shaft assembly.

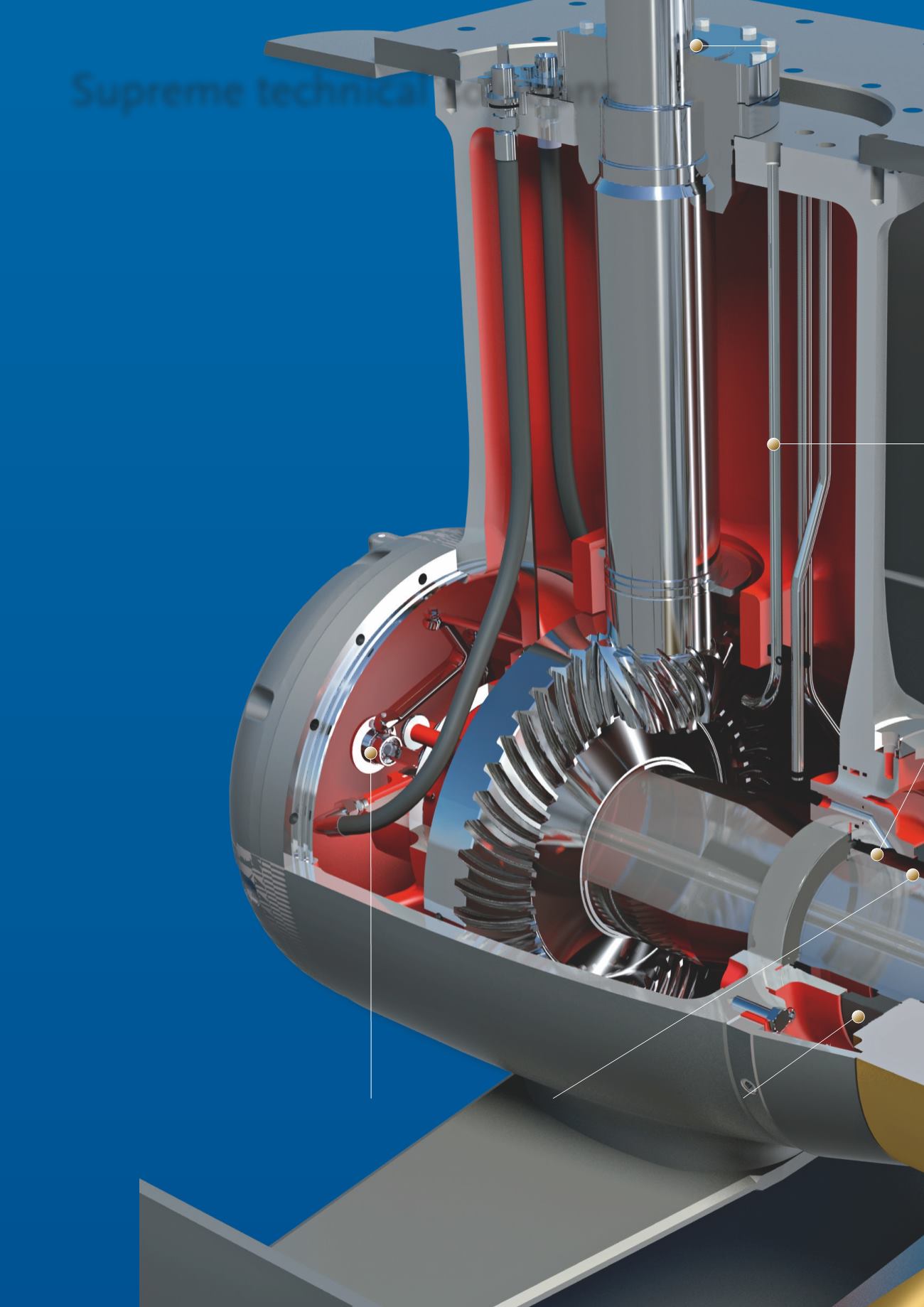

Supreme technical solutions

Brunvoll introduced propeller

shaft sealing systems with a

safety chamber and multiple

seals as early as 1965

Compact pitch

feedback mechanism

Ensures the precision needed

for today’s advanced control

systems and optimal DP

operation - without cumber-

some chains. The mechanical

transmission from the propeller

shaft to the feedback unit is

backlash-free.

Outer axial seal

The outer sealing unit is an axial

seal with specially finished

contact surfaces for stationary

and moving parts. This unit has

an inherent capability to absorb

wear, ensuring maximum

lifetime.

Safety chamber

The multiple-seal propeller shaft

sealing system combines an

axial seal and radial lip seals

separated by a drainable safety

chamber. This enables easy oil

sampling for inspection.

Pinion shaft seal

Radial lip seal with

dust cover.

12